Welcome to our blog on temperature-controlled warehousing in Georgia. In this article, we will explore the significance of temperature-controlled storage facilities, provide key statistics, and offer valuable insights to optimize your operations. Whether you are involved in the food, pharmaceuticals, or other industries that require temperature-sensitive storage, this blog will be a valuable resource for you.

The Importance of Temperature Controlled Warehousing

- Maintaining Product Quality: Understanding the critical role of temperature control in preserving and extending the shelf life of perishable goods.

- Regulatory Compliance: Exploring the stringent regulations enforced by organizations like the FDA, USDA, and CDC to ensure product safety and consumer health.

- Minimizing Losses: Highlighting the financial impact of temperature deviations and the importance of preventative measures to reduce wastage and financial losses.

Key Statistics on Temperature Controlled Warehousing

- Market Size and Growth: Analyzing the global market for temperature-controlled warehousing and its projected growth in the coming years.

- Industry Segmentation: Examining how various industries, such as pharmaceuticals, food and beverages, and chemicals, contribute to the demand for temperature-controlled storage.

- Regional Focus: Presenting statistics and trends specific to temperature-controlled warehousing in Georgia, including market size, revenue, and growth prospects.

Education on Temperature Controlled Warehousing

- Best Practices: Outlining the best practices for managing temperature-controlled storage facilities, including temperature monitoring, maintaining cold chain integrity, and optimizing warehouse layouts.

- Technology Advancements: Investigating the latest technological advancements, such as sensor technology and Internet of Things (IoT), that enable real-time monitoring and ensure continuous temperature control.

- Training and Certification: Discussing the importance of employee training and certification programs to ensure proper handling of temperature-sensitive products and compliance with industry standards.

Optimization Strategies for Temperature Controlled Warehousing

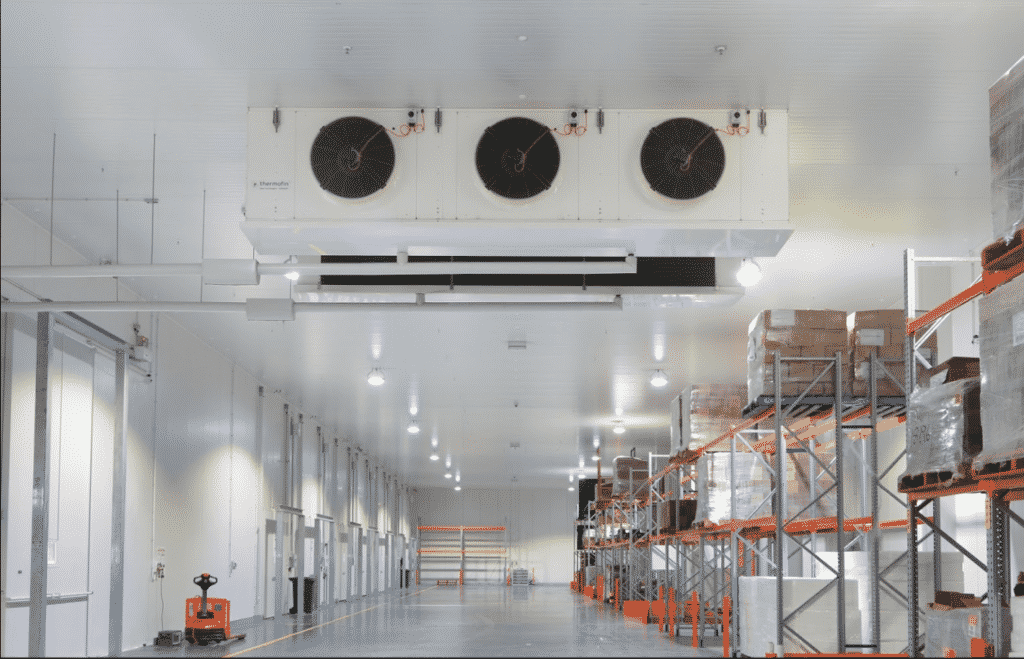

- Warehouse Design: Exploring warehouse layout and design considerations to maximize storage capacity, minimize temperature fluctuations, and optimize workflow.

- Energy Efficiency: Introducing energy-efficient solutions like insulation, LED lighting, and intelligent cooling systems to reduce operational costs and environmental impact.

- Inventory Management: Highlighting the importance of accurate inventory tracking, rotation, and FIFO (First In, First Out) practices to minimize product spoilage and maximize revenue.

Conclusion

In conclusion, temperature-controlled warehousing plays a vital role in preserving product quality, ensuring compliance, and minimizing losses for industries that deal with temperature-sensitive goods. By following best practices, leveraging technology, and implementing optimization strategies, businesses in Georgia can enhance operational efficiency and maintain the integrity of their products throughout the supply chain.

Dave McGowan has been a member of the WEL Family since May 1989. He is a husband and father of two children. Dave is also a U.S. Army veteran and served in Vietnam in 1971-1972, and he attended driving school soon after he was released from the military in 1974.

Dave McGowan has been a member of the WEL Family since May 1989. He is a husband and father of two children. Dave is also a U.S. Army veteran and served in Vietnam in 1971-1972, and he attended driving school soon after he was released from the military in 1974. During his career with WEL, Phil has worked as a driver, dispatcher, terminal manager and customer service manager. He says he always was a driver first, though non-driving jobs taught him financial management that helps him as an owner-operator.

During his career with WEL, Phil has worked as a driver, dispatcher, terminal manager and customer service manager. He says he always was a driver first, though non-driving jobs taught him financial management that helps him as an owner-operator.